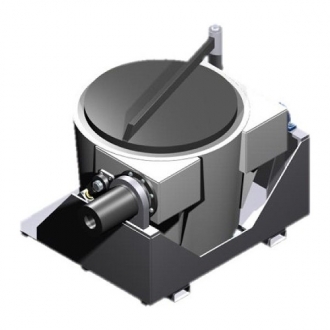

Tilting Coaxial transfer ladle with fixed-point discharge

SVBC-600

Characteristics

A new concept of transfer ladle for liquid Al alloy, that combines the practicality of use for greater security in the handling and transfer of the metal in the furnace. Allows the refilling the metal in the holding furnace waiting by checking a single movement (hydraulic) without having to perform the constant corrections necessary to position the forklift similar actions performed by a traditional ladle. The tilting movement is made by two hydraulic cylinders that use the oil of hydraulic lift truck itself. They are equipped with extensive safety features: pilot check valves to prevent the uncontrolled return in case of breakage of hoses and flow regulators to have a constant speed tilting and to ensure the proper flow of molten alloy.The easy-open lid with manual lock prevents spills during transport and metal allows a wide clearance for refilling up the furnace.

|

Capacity |

600 Kg of molten aluminium |

|

Weight without liquid metal |

1750 Kg |

|

Electric necessity |

Not required |