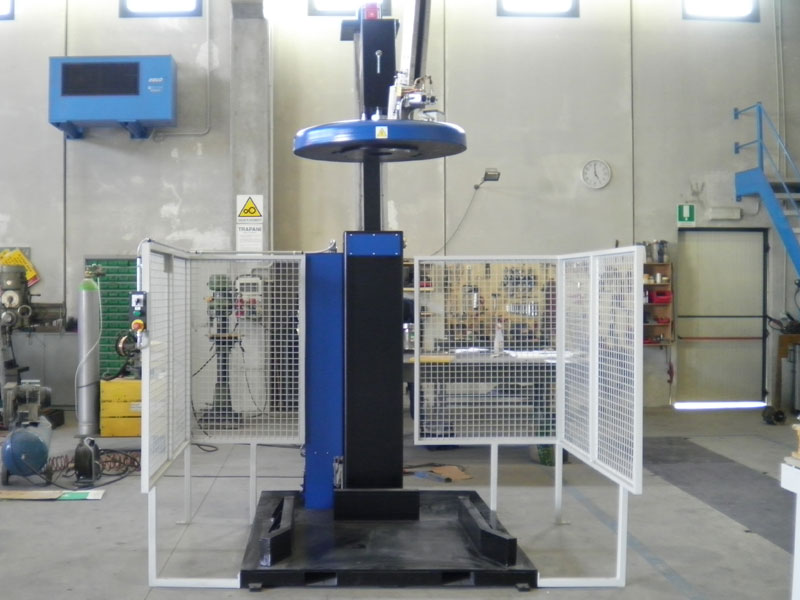

ADCD1 - ADCD2 - ADSD1 - ADSD2

Charactersitcs

This plant is born for foundries, that have the necessity of traditional degassing with inert gas and of modifying alloy too. The plant uses a disperser (lance and right rotor) that rotating at high speed, injects, in homogenous way, inert gas in the molten alloy.The high rating of removing pollutants and not desiderated particles as gas H2 dissolved, intermetallic segregations, mixed oxides of Al2O3 e SiO2 , SiC, comes from the minimal dimensions of used gas bubbles.

The refining is realized by introduction, in molten alloy, of particular pre-loaded capsules containing flux necessary for customer request.

These capsules are of aluminium, hermetically sealed, can contain salts, refining substances, sodium or mix of different elements for every metallurgic requirement.

This is the peculiarity of this plant: using right expedients during lance building and a complex program rotation management, it can sink the capsule on the bottom of landle, before the aluminium can melts itself and disperses its contained homogenously and rationally in the low/central zone of bath. The immediate and homogenous dispersion of contained elements is realized with great efficiency by centrifugal force generated by lance rotation. All the process parameters, as quantity and kind of capsules, times and rotation speed are completely programmable; you have 99 working programs so to process different alloys and to work in different conditions.

The advantages of this system can be translated in:

This is the peculiarity of this plant: using right expedients during lance building and a complex program rotation management, it can sink the capsule on the bottom of landle, before the aluminium can melts itself and disperses its contained homogenously and rationally in the low/central zone of bath. The immediate and homogenous dispersion of contained elements is realized with great efficiency by centrifugal force generated by lance rotation. All the process parameters, as quantity and kind of capsules, times and rotation speed are completely programmable; you have 99 working programs so to process different alloys and to work in different conditions.

The advantages of this system can be translated in:

- High flexibility of use, for the possibility to mix different products, packaged in cans easily managed and identifiable.

- Elimination of problem of salts diffusion coaxially to lance, as melting of them that blocked the lance; because of the same reason chemical products with a low melting point, can be used to have an immediate diffusion in alloy.

- Handling of the capsules; it is not necessary particular attention because sealed hermetically, easy and economical to handle and manage.

- manual hydraulic pump for lifting emergency.

- printer for reports of end of cycle with evolved operator panel.

- powder dispenser replaceable in one or both dose-capsules.

| Mechanical characteristics | |

|---|---|

| Plate vertical stroke | 1366 mm |

| Plate vertical speed | 4,5 mt./min. |

| Lance rotation speed | 100-700 rpm |

| Plate diameter | 1000 mm |

| Machine weight | 2000 Kg |

| Electrical characteristics | |

| Power | 3 Kw |

| Operating voltage | 400 V+N |

| Frequency | 50 Hz |

| Auxiliary voltages | 220/110 AC |