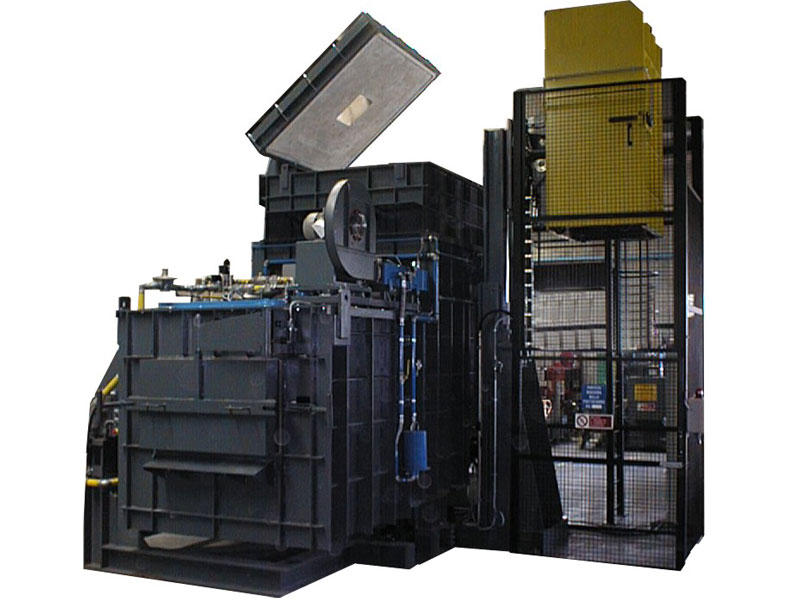

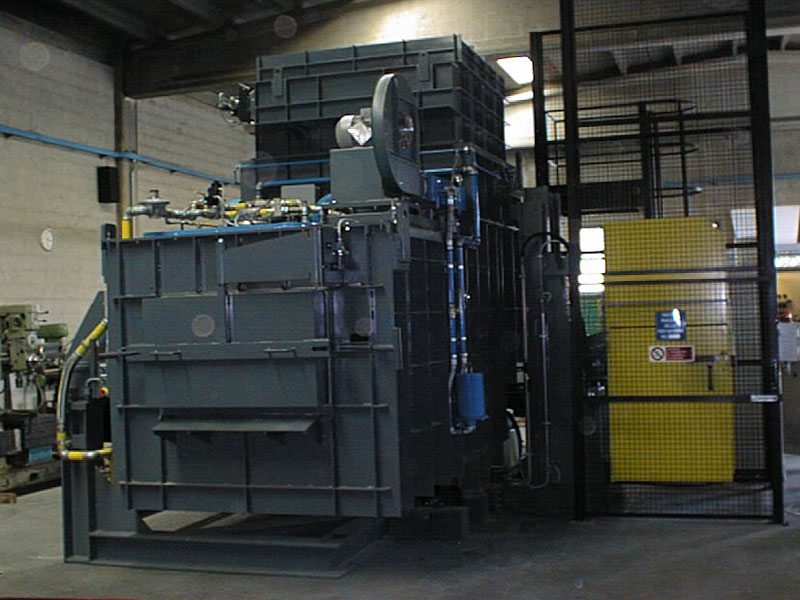

Stack melting reverberatory furnace

FF5 1000 - FF5 1500 - FF5 2000

Characteristics

Gas combustion furnace, tower-type, reversing on casting spout for melting of aluminium alloys. High efficiency resulting from "tower" conformation; the chambers side by side ensure performances and sturdiness. Automatic loader managed by software.

|

Option 1 |

|

Tank capacity |

2500 Kg of molten aluminium |

|

Melting capacity |

1000 - 1500 Kg / h. |

|

Max rating |

950.000 KCal/h |

|

Max consumption |

110 m3 / h |

|

Specific consumption |

70 m3 / Ton |

|

Option 2 |

|

Tank capacity |

3000 Kg of molten aluminium |

|

Melting capacity |

2000 Kg / h. |

|

Max rating |

950.000 KCal/h |

|

Max consumption |

180 m3 / h |

|

Specific consumption |

60 m3 / Ton |

|

Bath max temperature |

800 °C |

|

Refractory max temperature |

1000 °C |

|

Combustible gas |

Natural Gas - GPL on request |

|

Number of burners |

2 |

|

Installed power management |

From 0 to 100% with limit of maximum |

|

Power supply |

Three-phase, 380 V / 50 Hz |

|

Auxiliary services |

24 V C.C. / A.C. (Left out starting transformes and UV probes, working at 220 V A.C.) |

|

Continued and automatic control of molten aluminium temperature, by thermoregulator with thermocouple in the bath |

|

Thermo-limit of refractory temperature by thermoregulator not visualized and thermocouple in the wall |